When you think of ceramics-plates, tiles, vases, or even bathroom fixtures-you probably don’t picture a white powder. But that powder, calcium carbonate, is one of the quiet heroes behind every fired piece. It’s not flashy. It doesn’t glow or spark. But without it, most ceramics wouldn’t hold shape, wouldn’t glaze properly, and wouldn’t survive the kiln.

What calcium carbonate actually does in ceramics

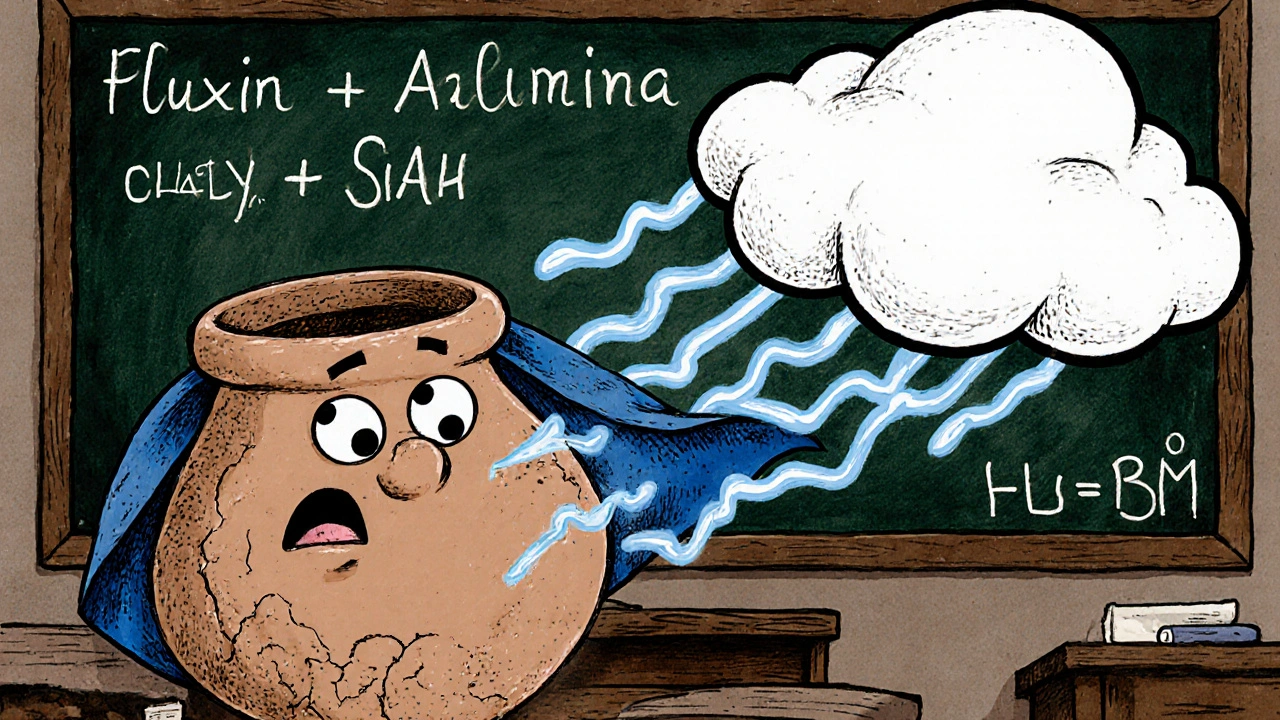

Calcium carbonate, or CaCO₃, is the same compound found in chalk, limestone, and seashells. In ceramics, it’s not just a filler. It’s a flux. That means it lowers the melting point of other materials in the clay body and glaze. When heated above 1,000°C, it breaks down into calcium oxide and carbon dioxide. The calcium oxide then reacts with silica and alumina to form glassy phases that bind everything together.

Without calcium carbonate, your clay body would need much higher firing temperatures-sometimes over 1,400°C-to achieve strength. That’s expensive, energy-intensive, and risky. Most industrial kilns aren’t built for that. Calcium carbonate lets manufacturers fire at 1,150-1,250°C and still get dense, durable ware. It’s the reason your ceramic mug doesn’t crack when you pour hot coffee into it.

How it affects clay bodies

In raw clay mixtures, calcium carbonate improves plasticity and reduces shrinkage during drying. It helps particles bind more evenly, which means fewer cracks before the kiln even turns on. Potters who work with earthenware often add 5-10% calcium carbonate to their recipes. For stoneware, it’s usually 2-5%, depending on the other ingredients.

Too much, though, and you get problems. Above 12%, calcium carbonate can cause bloating or warping. The carbon dioxide released during decomposition gets trapped, forming bubbles. That’s why ceramic labs test batches with X-ray diffraction and thermal analysis before large-scale production. It’s not guesswork-it’s chemistry.

The glaze game: why calcium carbonate is non-negotiable

Glazes are where calcium carbonate really shines. It’s a key ingredient in most matte and satin finishes. When mixed with feldspar, silica, and metal oxides, it helps form a stable, glassy surface that’s both waterproof and food-safe.

Think of a matte white glaze on a ceramic bowl. That smooth, non-glossy finish? It’s likely because calcium carbonate suppressed the formation of large glass crystals. Too little, and the glaze becomes too runny. Too much, and it turns cloudy or chalky. The sweet spot? Around 8-15% in most glaze recipes.

It also helps control thermal expansion. If the glaze expands or contracts too much compared to the clay body, it crazes (cracks) or shivers (flakes off). Calcium carbonate helps balance that. That’s why industrial manufacturers don’t just pick any limestone-they use high-purity, low-iron grades from specific quarries in Italy, Spain, or the U.S. Midwest.

Why purity matters

Not all calcium carbonate is the same. Industrial ceramics demand purity levels above 98%. Impurities like iron oxide, magnesium, or silica change the color, melting behavior, and strength of the final product.

Iron oxide, even at 0.1%, can turn a white glaze beige. That’s unacceptable for sanitary ware or tableware meant to look clean and bright. That’s why factories test incoming batches with spectrometers. They don’t just weigh it-they analyze it.

High-purity calcium carbonate is often ground to less than 2 microns. That fine particle size ensures even distribution in the mix. If particles are too coarse, you get spots, uneven glazing, or weak spots in the body.

Alternatives? Not many

You might wonder: can you replace calcium carbonate with something else? Dolomite (a mix of calcium and magnesium carbonate) is sometimes used, especially in low-fire glazes. But it changes the firing behavior and can make glazes more prone to crawling.

Calcium oxide (quicklime) is too reactive. It absorbs moisture from the air, clumps, and becomes hard to handle. Calcium sulfate? It doesn’t flux well and can cause bloating. So while alternatives exist, none match calcium carbonate’s balance of low cost, reliable performance, and compatibility with other ceramic materials.

Real-world impact: from tiles to dental crowns

Calcium carbonate isn’t just for pottery. It’s in the tiles on your kitchen floor. It’s in the porcelain insulators on power lines. It’s even in dental crowns and orthopedic implants made from bio-ceramics. In medical ceramics, it’s used to mimic the mineral content of human bone, helping implants bond better with tissue.

China, Italy, and Germany produce the majority of ceramic-grade calcium carbonate. The U.S. and Turkey are rising players. In 2024, global demand for ceramic-grade CaCO₃ hit 12 million metric tons-up 6% from 2022. That growth isn’t from fancy art pieces. It’s from mass-produced tiles, sanitary ware, and technical ceramics used in electronics and aerospace.

What happens if you skip it?

Try making a ceramic piece without calcium carbonate. You’ll find the clay is harder to throw, dries unevenly, and cracks during bisque firing. The glaze won’t melt properly-it’ll stay powdery or run off in patches. Even if you fire it longer, the result is brittle, porous, and weak.

It’s not just about aesthetics. It’s about function. A cracked tile leaks. A chipped plate can harbor bacteria. A failed insulator can short-circuit a transformer. Calcium carbonate isn’t optional. It’s a safety net built into the chemistry of everyday ceramics.

How to choose the right calcium carbonate

If you’re a ceramic artist or small producer, here’s what to look for:

- Purity: Minimum 98% CaCO₃. Avoid anything labeled "industrial grade" unless you know the impurity profile.

- Particle size: Less than 5 microns for glazes, 10-20 microns for clay bodies.

- Source: Limestone from stable geological formations (e.g., White Cliffs of Dover, Kentucky limestone) tends to be more consistent than crushed shell or recycled material.

- Testing: Ask for a certificate of analysis (CoA). Look for low iron (<0.05%), low magnesium (<0.5%), and low silica (<1%).

Don’t buy from suppliers who can’t provide this. Cheap calcium carbonate might save you $20 a bag-but cost you $200 in wasted kiln loads.

Final thought: the invisible backbone

Calcium carbonate doesn’t get credit. No one takes photos of it. No one writes poems about it. But every time you pick up a ceramic cup, sit on a porcelain toilet, or step on a glazed tile, you’re using something made possible by this simple compound.

It’s not magic. It’s science. And it’s working right under your nose-in the kiln, in the glaze, in the clay-turning rock into something beautiful and useful.

Is calcium carbonate safe in ceramic tableware?

Yes, when used properly. Calcium carbonate breaks down into calcium oxide during firing, which becomes part of the glassy matrix in glazes and clay bodies. Once fired, it’s chemically stable and non-toxic. Regulatory bodies like the FDA and EU Food Contact Materials Regulation approve ceramics with calcium carbonate for food use, as long as glazes are properly formulated and fired to maturity.

Can I use kitchen baking soda instead of ceramic-grade calcium carbonate?

No. Baking soda is sodium bicarbonate (NaHCO₃), not calcium carbonate. It decomposes at much lower temperatures (around 50°C) and releases carbon dioxide and sodium oxide-neither of which act as fluxes in ceramics. Using it will cause bloating, weak structures, and glaze defects. It’s not a substitute.

Why does my glaze bubble when I add calcium carbonate?

Bubbling usually means you’re adding too much (over 12%) or firing too quickly. Calcium carbonate releases CO₂ between 600°C and 900°C. If the kiln heats too fast, the gas can’t escape and gets trapped, forming bubbles. Slow down your bisque firing-especially between 600°C and 800°C-and reduce the percentage to 5-8%.

What’s the difference between precipitated and ground calcium carbonate?

Ground calcium carbonate is crushed limestone or marble. It’s cheaper and used in clay bodies. Precipitated calcium carbonate is chemically synthesized, often from lime slurry and CO₂. It’s purer, with tighter particle size control, and used in high-end glazes and technical ceramics. For most potters, ground is fine. For industrial production, precipitated is preferred.

Does calcium carbonate affect the color of ceramics?

Pure calcium carbonate is white and doesn’t add color. But if it contains iron oxide impurities-even 0.1%-it can yellow or brown your clay or glaze. That’s why ceramic suppliers test for iron content. For white or light-colored ware, always use low-iron calcium carbonate. For raku or terra cotta, a little iron is acceptable and even desirable.

Leslie Schnack

October 31, 2025 AT 02:02I never realized how much chemistry goes into something as simple as a ceramic mug. The part about calcium carbonate balancing thermal expansion made me think about why my favorite bowl never cracks when I microwave soup. It’s wild how such a tiny ingredient holds the whole thing together.

Also, the bit about high-purity limestone from Italy? That’s next-level specificity. I’m now weirdly curious about where my local pottery supply sources its chalky powder.

Hazel Wolstenholme

October 31, 2025 AT 03:05How quaint. You’ve reduced a sophisticated ceramic flux system to a ‘quiet hero’ narrative, as if calcium carbonate were some sort of unsung knight in a medieval epic. The reality? It’s a stoichiometric workhorse-unremarkable, predictable, and utterly replaceable in theory, though no one dares because of institutional inertia and the terrifying specter of glaze crawling.

And please, spare me the romanticization of ‘White Cliffs of Dover limestone.’ That’s not proven superiority-it’s brand loyalty masquerading as geology. Try sourcing from the Tertiary chalk of the Paris Basin; now *that’s* purity with pedigree.

Matthew Kwiecinski

November 1, 2025 AT 23:15Calcium carbonate isn’t magic. It’s just a mineral that decomposes at 825°C. The real story is how the industry standardized around it because it’s cheap and abundant, not because it’s optimal. Every other flux system-magnesium, barium, even lithium-has advantages. But changing suppliers means retesting every glaze, retraining every technician, and that’s too much risk for a market that profits on consistency, not innovation.

Also, the 98% purity claim? That’s marketing. Most commercial grades are 95-97%. The labs are just being polite.

Justin Vaughan

November 2, 2025 AT 19:00Let me tell you something-this is why I love ceramics. It’s not about the wheel or the glaze colors. It’s about the invisible science that makes it all work. Calcium carbonate? It’s the quiet backbone of the whole damn craft.

I used to think my cracks were from my throwing technique. Turns out, I was using cheap chalky stuff from the hardware store. Switched to ceramic-grade from a reputable supplier, dropped 5% into my stoneware, and suddenly my pieces went from ‘maybe survives firing’ to ‘can hold soup for 20 years.’

If you’re a maker, don’t cheap out on this. It’s not just chemistry-it’s peace of mind. Your future self will thank you when your mug doesn’t explode in the dishwasher.

Manuel Gonzalez

November 4, 2025 AT 12:18Interesting read. I’ve always assumed glazes just melted and became glass. Never thought about the role of calcium carbonate in controlling expansion or preventing crazing.

Also, the part about particle size being under 5 microns for glazes makes sense-fine powders disperse better. I’ve had issues with clumping before, and now I know why.

Good to see the emphasis on testing. Too many hobbyists skip the CoA and wonder why their white glaze turns gray. It’s not magic. It’s math.

Brittney Lopez

November 4, 2025 AT 21:10This was so helpful! I’m just starting out in ceramics and I’ve been terrified of glaze recipes. Knowing that calcium carbonate is the key to stability gives me so much confidence to experiment.

Also, thank you for mentioning the dental crowns-that’s wild! I had no idea the same stuff in my tiles is in my dentist’s lab. Makes me feel connected to something bigger.

Jens Petersen

November 6, 2025 AT 14:04Oh, so now we’re glorifying limestone as if it were a sacred text? This is the same lazy thinking that lets people believe ‘natural’ means ‘better.’ Calcium carbonate is a boring, ubiquitous mineral that exists because the Earth is made of dead sea creatures and sediment. The fact that your ceramic mug doesn’t shatter isn’t a triumph of chemistry-it’s a failure of imagination.

And don’t get me started on the ‘high-purity’ obsession. You’re paying premium prices for a substance that, if you actually understood phase diagrams, you’d realize you could substitute with 30% less cost and better thermal properties if you weren’t so attached to tradition.

This post reads like a corporate brochure written by someone who’s never fired a kiln outside a factory line.

Keerthi Kumar

November 7, 2025 AT 11:21Dade Hughston

November 8, 2025 AT 03:14